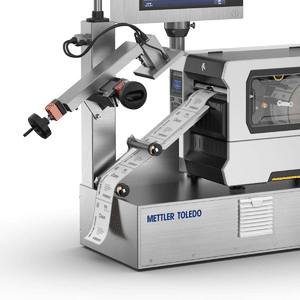

This compact system prints and inspects labels using Smart or High-Resolution Camera technology. Faulty labels are detected and can be removed before they are applied to products, ensuring only correct labels are used.

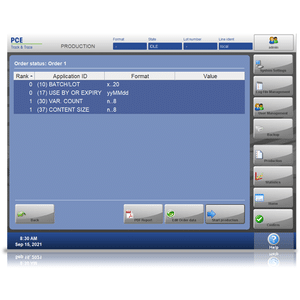

Supports Variable Formats

Supports pharmaceutical serialization, medical device UDI or clinical trial labeling. Data can be dynamically assigned to PDF templates.

Flexible Label Production

Use the peel-off mode to print and verify labels during production or use the rewind mode to prepare label batches for reel-to-reel label production.

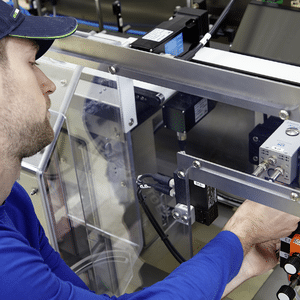

Compact Design

An ergonomic design enables comfortable and efficient product handling. The space-saving design allows simple integration in confined environments.

Precise Label Processing With Flexibility for Variable Formats

Discover how it transforms IMPs label printing for clinical trials 🡢

| Track & Trace Solution | Serialization Mark & Verify |

| Product Types | Labels |

| System Design | manual |

| Reading Devices | Smart Camera High Resolution Camera |

| Number of Reading Devices | 1 |

| Throughput | manual |

| Compatible Software | PLM Mark & Verify PLM Direct PLM Serialization |

| Dimensions (H x W x D) | 1291 x1253 x 552 mm |

| Product Height | max. 230 mm |

| Product Width | 30 – 170 mm |

| Product Length | 30 – 250 mm |

| HMI | 15″ 15″” |

Print and inspect labels for later application to the package. Efficient for either small batches or frequent product changeovers.

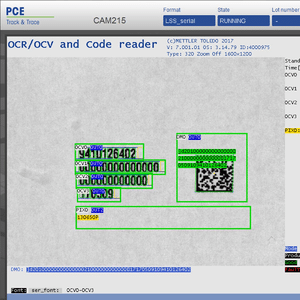

Use a Smart Camera or High-Resolution Camera depending on the label size and print resolution for optimum verification of label information.

As labels are printed, an integrated camera verifies that all information is present and correct.

Additional Track and Trace serialization capabilities can be enabled on the software as business needs grow.

The mark and verify software option supports simple code inspections. As business needs change, easily upgrade to the advanced functionality of the PCE Line Manager (PLM) for serialization.

For optional serialization requirements use PCE Line Manager (PLM) software for complete line control of all production processes. Choose PCE Site Manager (PSM) for enterprise integration with site-wide IT infrastructure.

A global network of service experts provides fast remote and on-site support. Our comprehensive service offering allows you to achieve regulatory compliance, high performance, and maximum uptime throughout the life cycle of your product inspection equipment.