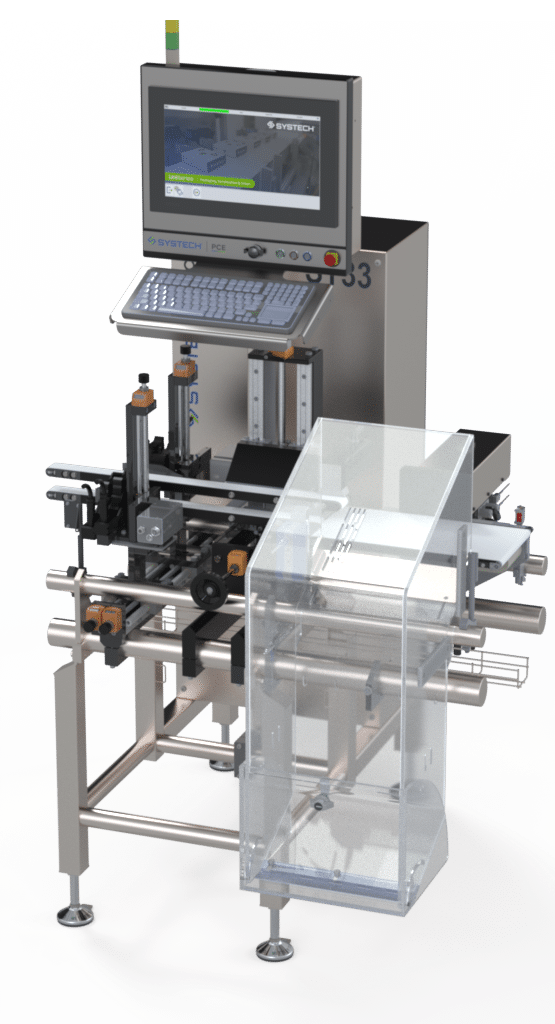

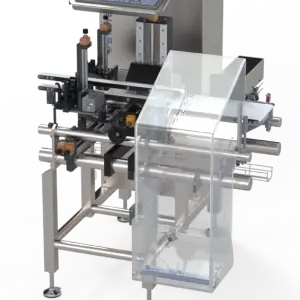

Compact serialization system for easy integration into production lines. Performs all functions for serialization, including marking, recording and verification of all serialization data.

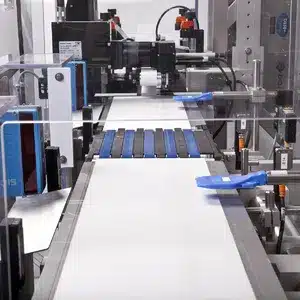

Fully Automated Processing

Automated item-by-item serialization with advanced tracking, precise printing, and quality verification.

Efficient Product Handling

High production line speeds up to 600 ppm for a wide range of package sizes and easy product changeovers—product handling at its best.

Compact and Space-Saving Design

Designed to use minimal production line space, ideal for any production environment.

|

Track & Trace Solution |

Serialization |

|

Packaging Level |

Carton |

|

Dimensions (H x W x L) |

1923mm (H) x 1039mm (W) x 1339mm (L) |

|

Material |

Stainless Steel |

|

Code Specification |

1D, 2D, QR |

|

Throughput |

Automated; up to 600 ppm |

|

Flow |

Left to Right |

|

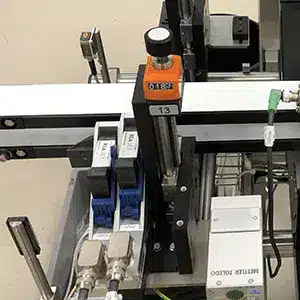

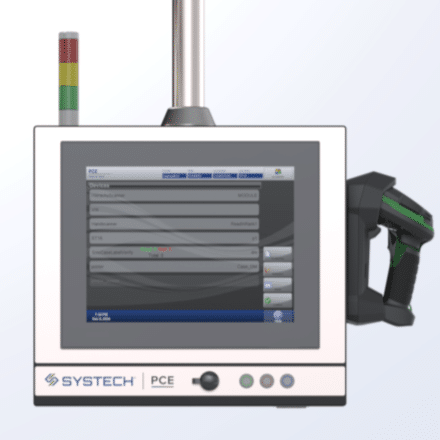

Reading Devices |

Up to 3 Smart Cameras (SMC), Hand Scanner |

|

Printers |

Ink Jet Printer (1 Controller, up to 6 Print Heads) |

|

User Interface |

15.6″ (16:9) or 15″ (4:3) |

|

Compatible Software |

UniSeries, PLM |

|

Product Compliance |

CE, ETL, CB, FCC, RoHS |

|

Product Height (H) |

For both Versions 150 & 250:

10 mm to 100 mm

10 mm to 200 mm with product height extension |

|

Product Width (W) |

For both Versions 150 & 250: 45 mm to 200 mm |

|

Product Length (L) |

Variant 150: 25 mm to 150 mm

Variant 250: 25 mm to 250 mm |

|

Product Weights |

Variant 150: 1g to 300g

Variant 250: 1g to 1100g |

Choose printers and Smart Camera options as needed to help ensure products are compliant with the current regulations.

Advanced counter-check sensors ensure only products meeting quality standards stay on the production line.

Evaluate the data matrix codes in line with ISO 15415 standard. Validate the print quality during the production process for advanced line performance.

With easily accessible parts for cleaning and maintenance, the system complies with Good Manufacturing Practice (GMP).

Use Systech UniSeries or PLM software for complete line control of serialization. Choose UniSeries or PLM for enterprise integration with site-wide IT infrastructure.

Meets current regulatory requirements and is easily upgradeable for future requirements and regulations. As regulations change, simple and quick software updates help protect the hardware investment in the long term.

Our global network of Systech service experts ensures rapid remote and on-site response, wherever your operations are. From installation and validation to ongoing maintenance, our support model is designed to maximize system uptime, safeguard compliance and global serialization and regulatory requirements and extend the performance lifecycle of your inspection and track & trace solutions.