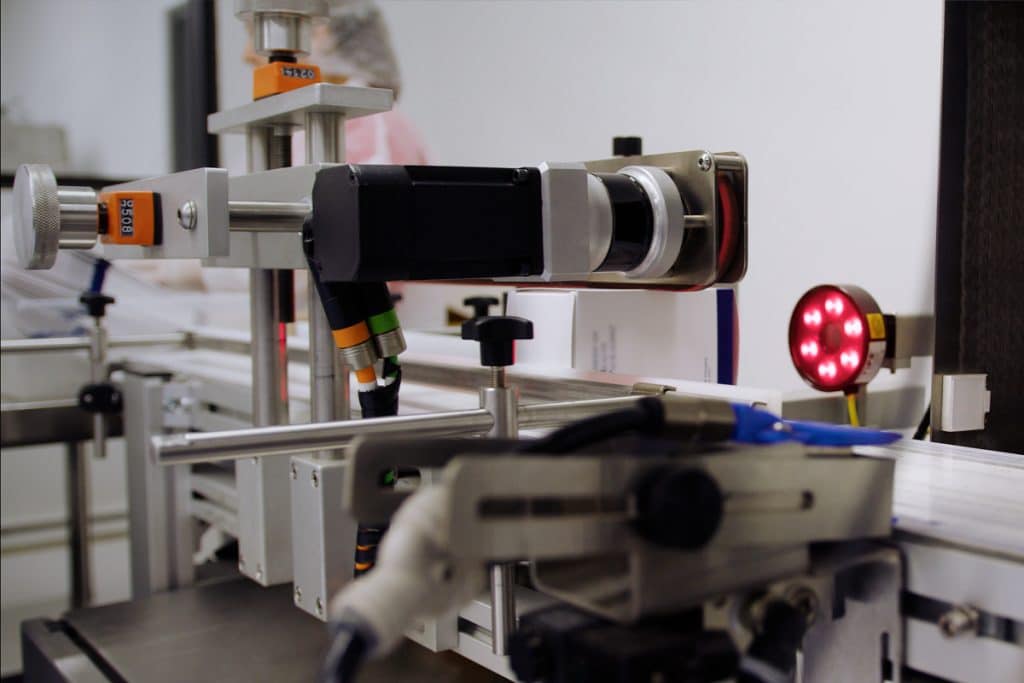

Systech now offers UniSeries software that can be paired with a range of Systech packaging, serialization, inspection and aggregation hardware. Start with an Integration Kit or deploy integrated offerings with fully automated workflows, solution for all of your packaging line needs.

If you have limited facility space, Systech’s turnkey software and hardware is perfect for maximizing your production footprint in a compact packaging environment, so you can achieve a level of capacity that typically requires far greater square footage.

With hardware and software integrated as single solution, your IT staff will recoup precious time that was previously spent on complex configurations and deployments so they can focus on other important infrastructure issues.

Buying a turnkey solution from Systech means you only have one company to contact whether you’re troubleshooting a software or hardware issue.

With new hardware, you avoid the expense of repairs and the need for inventory spare parts that comes from using aging, secondhand or refurbished equipment.

Our turnkey solution provides an interconnected system that reduces time spent switching between interfaces and speeds up data transmission, enabling faster line speeds and fewer errors.

New equipment may come with a higher upfront cost, but when you factor in repairs, maintenance and labor, and lost productivity from downtime, you’ll find you save money years down the road by having a consistently higher line throughput.

Let’s discuss how UniSeries can help you save money, enhance efficiency and drive revenue growth.