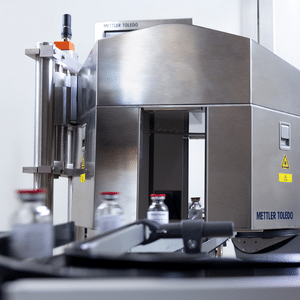

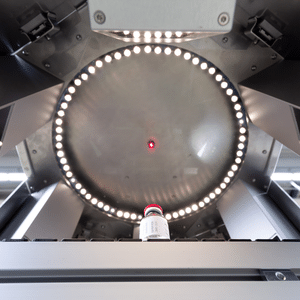

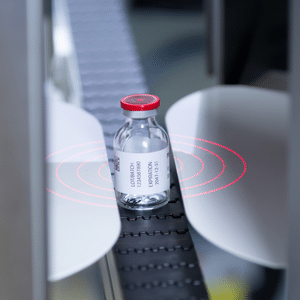

La sérialisation utilise 6 capteurs d'image pour capturer une vue à 360° de n'importe quel contenant rond, comme les bouteilles ou les flacons. La conception compacte est optimisée pour s'adapter aux convoyeurs existants afin de perturber le moins possible les lignes de production.

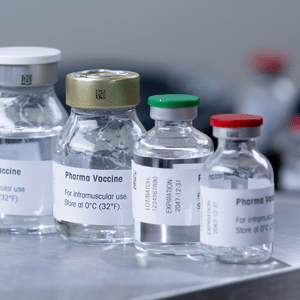

Sérialisation pour tout conteneur rond

Sérialisez les étiquettes sur les bouteilles, les flacons et les boîtes grâce à une vue complète à 360° de l'emballage, avec une perturbation minimale de l'efficacité de la production existante.

Prise en charge d'une gamme de tailles d'emballages ronds

S'adapte aux emballages ronds tels que les bouteilles, les boîtes ou les flacons de 10 mm à 110 mm en utilisant une lentille focale fixe ou une lentille liquide.

Lit les codes de sérialisation de petite taille

Choisissez notre tête d'inspection 360° à lentille focale fixe ou à lentille liquide pour lire des modules aussi petits que 0,2 mm par code.

| Solution de suivi et de traçabilité | Sérialisation |

| Types de produits | Flacons Consommateurs Les flacons Les flacons Flacons D'autres flacons D'autres flacons D'autres encore Rondes |

| Conception du système | intégré |

| Dispositifs de lecture | Capteur de luminescence Caméra intelligente 360 Tête de balayage Scanner laser Caméra intelligente |

| Nombre de dispositifs de lecture | jusqu'à 4 |

| Débit | jusqu'à 300 ppm |

| Logiciel compatible | Sérialisation PLM |

| Dimensions (H x L x P) | 394 x 589 x 510 mm |

| Hauteur du produit | max. 230 mm |

| Largeur du produit | 6 - 110 mm de diamètre |

| IHM | 15″ 15″” |

Choisissez parmi plusieurs options logicielles PCE pour gérer les dispositifs de production (imprimante, tête d'inspection à 360°, caméras supplémentaires et dispositifs de rejet) et connectez-vous aux environnements ERP, MES ou cloud actuels.

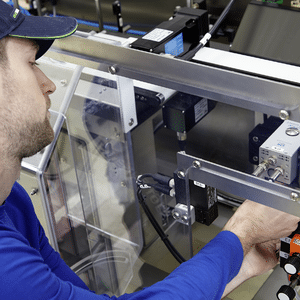

Choisissez le boîtier électrique, l'armoire et l'IHM nécessaires à votre application. Installez la tête d'inspection à 360° sur les lignes existantes ou utilisez un cadre autonome pour répondre aux besoins d'espace.

Utilisez une caméra intelligente supplémentaire pour lire les informations imprimées au jet d'encre, telles que les codes d'aide sérialisés ou les dates de péremption sur les bouchons ou les couvercles. Peut détecter l'encre noire et l'encre UV.

vous aide à respecter les normes réglementaires internationales, telles que les BPF (bonnes pratiques de fabrication), les pratiques de la FDA 21 CFR Part 11 ou d'autres normes propres à votre région.

Le boîtier en acier inoxydable conforme à la norme IP65 contribue à minimiser les interférences de la lumière ambiante, ce qui permet une lecture efficace des codes sur une variété de surfaces d'impression (étiquettes, plastique, métaux) à l'aide des 6 capteurs d'image.

Permet d'inspecter les étiquettes déjà sérialisées pour vérifier la conformité des processus existants, ajoutant ainsi une étape supplémentaire pour s'assurer que les étiquettes répondent à vos normes de qualité.

Un réseau mondial d'experts en services fournit une assistance rapide à distance et sur site. Notre offre de services complète vous permet d'atteindre la conformité réglementaire, des performances élevées et une disponibilité maximale tout au long du cycle de vie de votre équipement d'inspection de produits.