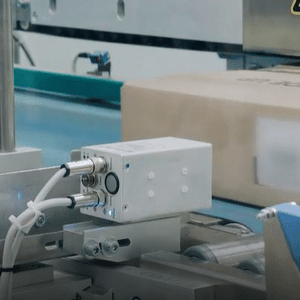

Marquage et vérification de la qualité d'impression sur l'emballage des produits avec trois types de vérification disponibles : Présence, Qualité et Contrôle de référence. S'intègre directement sur les lignes de production ou à l'intérieur des machines d'emballage, en se connectant facilement aux imprimantes existantes.

Conception modulaire et compacte

La conception compacte et les composants modulaires s'intègrent facilement dans les lignes de production ou les nouveaux équipements d'emballage avec un encombrement minimal.

Assurance qualité automatisée

Fournit une assurance qualité en ligne de l'emballage des produits en détectant les erreurs d'impression ou d'étiquetage le plus tôt possible dans le processus de production.

Prise en charge de plusieurs capteurs

Il prend en charge plusieurs capteurs tels que des caméras intelligentes, des lecteurs de codes-barres ou des lecteurs de machines et fournit des contrôles de présence, de qualité et de référence.

| Solution de suivi et de traçabilité | Marquer et vérifier |

| Types de produits | Cartons Cartons Cartons Orientés Étiquettes Fardeaux Les étuis Les étuis Les étuis Caisses Palettes |

| Conception du système | intégré |

| Dispositifs de lecture | Capteur de luminescence Tête de balayage Scanneur laser Caméra intelligente |

| Nombre de dispositifs de lecture | jusqu'à 6 |

| Débit | jusqu'à 300 ppm |

| Logiciel compatible | PLM Mark & Verify |

| IHM | 15″ 15″” |

Les capteurs, les caméras et les composants sont dotés de boîtiers compacts qui réduisent l'exposition aux débris et à la poussière, ce qui permet d'obtenir des résultats fiables et précis et de réduire au minimum les temps d'arrêt liés à la maintenance.

Les inspections peuvent être effectuées sur une grande variété de produits tels que les blisters, les comprimés, les notices, les cartons ou les caisses - en effectuant des inspections sur une étiquette ou directement sur le produit. Les principales vérifications sont la présence, la qualité ou le contrôle de référence d'un attribut.

Le contrôle de présence permet de vérifier qu'un attribut requis est présent. Le contrôle de qualité permet de s'assurer qu'un attribut possède la qualité requise. La vérification de la référence permet de vérifier que l'attribut correspond à une référence donnée. Toutes les méthodes peuvent être combinées selon les besoins.

L'analyse en ligne de la qualité d'impression du code datamatrix pendant le processus de production, conformément à la norme ISO 15415, permet d'améliorer les performances de la ligne.

Répond aux exigences des BPF et peut être facilement mis à niveau pour répondre aux besoins futurs. Lorsque les réglementations changent, des mises à jour logicielles simples et rapides permettent de protéger l'investissement matériel à long terme. Les systèmes Mark & Verify peuvent être transformés en systèmes de sérialisation.

Un réseau mondial d'experts en services fournit une assistance rapide à distance et sur site. Notre offre de services complète vous permet d'atteindre la conformité réglementaire, des performances élevées et une disponibilité maximale tout au long du cycle de vie de votre équipement d'inspection de produits.