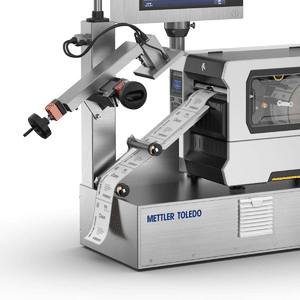

Ce système compact imprime et inspecte les étiquettes à l'aide de la technologie Smart ou de la caméra haute résolution. Les étiquettes défectueuses sont détectées et peuvent être retirées avant d'être appliquées sur les produits, ce qui garantit que seules les étiquettes correctes sont utilisées.

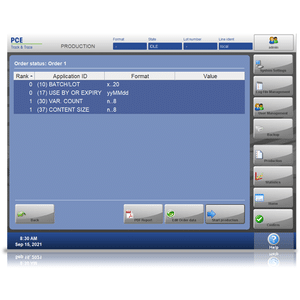

Prise en charge des formats variables

Prise en charge de la sérialisation des produits pharmaceutiques, de l'UDI des dispositifs médicaux ou de l'étiquetage des essais cliniques. Les données peuvent être affectées dynamiquement aux modèles PDF.

Production d'étiquettes flexibles

Utilisez le mode décollage pour imprimer et vérifier les étiquettes pendant la production ou utilisez le mode rembobinage pour préparer des lots d'étiquettes pour la production d'étiquettes en bobine.

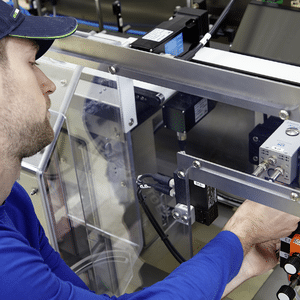

Conception compacte

Une conception ergonomique permet une manipulation confortable et efficace des produits. La conception peu encombrante permet une intégration simple dans les environnements restreints.

Traitement précis des étiquettes avec flexibilité pour les formats variables

Découvrez comment il transforme Impression d'étiquettes d'IMPs pour les essais cliniques 🡢

| Solution de suivi et de traçabilité | Sérialisation Marquer et vérifier |

| Types de produits | Étiquettes |

| Conception du système | manuel |

| Dispositifs de lecture | Caméra intelligente Caméra intelligente Caméra intelligente Caméra intelligente Caméra haute résolution |

| Nombre de dispositifs de lecture | 1 |

| Débit | manuel |

| Logiciel compatible | PLM Marquer et Vérifier PLM Direct Sérialisation PLM |

| Dimensions (H x L x P) | 1291 x1253 x 552 mm |

| Hauteur du produit | max. 230 mm |

| Largeur du produit | 30 - 170 mm |

| Longueur du produit | 30 - 250 mm |

| IHM | 15″ 15″” |

Imprimez et contrôlez les étiquettes en vue de leur application ultérieure sur l'emballage. Efficace pour les petits lots ou les changements fréquents de produits.

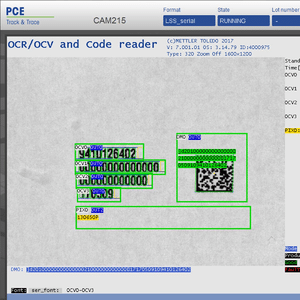

Utilisez une caméra intelligente ou une caméra haute résolution en fonction de la taille de l'étiquette et de la résolution d'impression pour une vérification optimale des informations de l'étiquette.

Lors de l'impression des étiquettes, une caméra intégrée vérifie que toutes les informations sont présentes et correctes.

Des fonctionnalités supplémentaires de sérialisation Track and Trace peuvent être activées sur le logiciel au fur et à mesure de l'évolution des besoins de l'entreprise.

L'option logicielle de marquage et de vérification permet d'effectuer de simples inspections de code. Au fur et à mesure de l'évolution des besoins de l'entreprise, il est facile de passer à la fonctionnalité avancée du gestionnaire de ligne PCE (PLM) pour la sérialisation.

Pour les besoins optionnels de sérialisation, utilisez le logiciel PCE Line Manager (PLM) pour un contrôle complet de tous les processus de production. Choisissez PCE Site Manager (PSM) pour l'intégration de l'entreprise avec l'infrastructure informatique du site.

Un réseau mondial d'experts en services fournit une assistance rapide à distance et sur site. Notre offre de services complète vous permet d'atteindre la conformité réglementaire, des performances élevées et une disponibilité maximale tout au long du cycle de vie de votre équipement d'inspection de produits.