Cette solution puissante associe la sérialisation éprouvée des articles à un pesage de haute précision utilisant la technologie FlashCell™ EMFR et à l'inspection visuelle de l'étiquette du produit et de la maquette. La conception compacte comporte une seule interface homme-machine pour une utilisation intuitive.

Conception du système

Nombre de dispositifs de lecture

Ce logiciel permet un contrôle unifié des lignes pour chaque capteur, caméra, imprimante et lecteur de code impliqué dans le processus d'agrégation. Adaptable à de multiples scénarios d'agrégation, il simplifie la gestion de la chaîne d'approvisionnement et les processus d'entreposage.

Conception du système

Nombre de dispositifs de lecture

PLM Direct est le logiciel idéal pour la sérialisation et l'agrégation sur une ligne de production unique dédiée. L'échange de données avec les systèmes de niveau 3 et 4 est géré à l'aide de formats XML standard, ce qui facilite l'intégration dans les processus existants.

Conception du système

Nombre de dispositifs de lecture

PLM Mark & Verify aide à prévenir les rappels de produits et à préserver la réputation de la marque en vérifiant la présence, la référence et la qualité de l'emballage et de l'étiquetage. Plusieurs options d'inspection sont disponibles, par exemple l'inspection de codes, d'étiquettes, de blisters ou de textes.

Conception du système

Nombre de dispositifs de lecture

Ce logiciel offre un contrôle global, servant d'interface unifiée pour aider à surveiller et à gérer la sérialisation. Des scénarios de sérialisation prédéfinis simplifient le processus de production.

Conception du système

Nombre de dispositifs de lecture

Gestion des lignes de production à l'échelle du site, permettant une visibilité des données de l'ensemble du processus de suivi et de traçabilité. Le PSM offre en outre une connectivité avancée avec les systèmes ERP ou MES, ce qui permet d'étendre les processus existants de gestion des stocks ou de contrôle des lignes.

Conception du système

Nombre de dispositifs de lecture

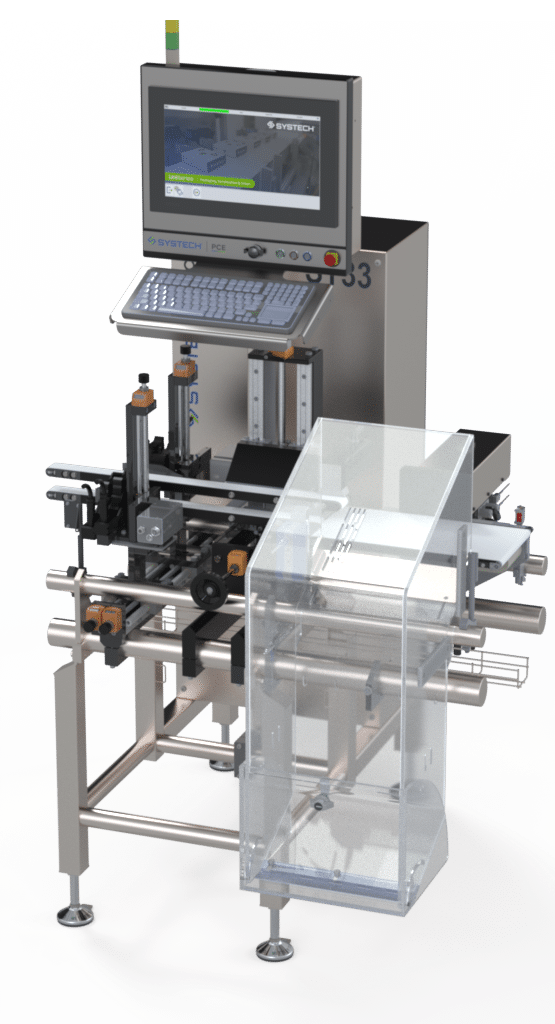

Parce que la vitesse, la précision et la conformité sont importantes. Le SMC450 est conçu pour les environnements à haut débit qui exigent précision, flexibilité et durabilité, le tout dans un format compact et robuste.

Conception du système

Nombre de dispositifs de lecture

A Cette solution clé en main est conçue pour aider les entreprises pharmaceutiques à optimiser leurs opérations tout en garantissant la sécurité des produits et la conformité aux réglementations. La solution prend en charge l'agrégation manuelle article par article et offre une solution prête à l'emploi, flexible pour le retraitement en cours de lot et après le lot dans l'atelier de production.

Conception du système

Nombre de dispositifs de lecture

Le ST16 est une solution prête à l'emploi qui permet d'agréger rapidement les caisses et d'inspecter les étiquettes des caisses. Le logiciel semi-automatique Pack-By-Layer (ou Count-By-Layer) maximise la productivité tandis que le design ergonomique permet une utilisation intuitive.

Conception du système

Nombre de dispositifs de lecture

Système de sérialisation compact pour une intégration facile dans les lignes de production. Exécute toutes les fonctions de sérialisation, y compris le marquage, l'enregistrement et la vérification de toutes les données de sérialisation.

Conception du système

Nombre de dispositifs de lecture

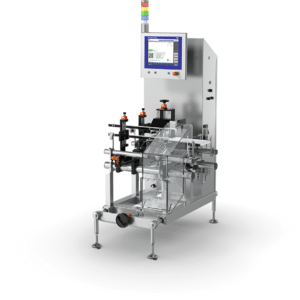

Ce système compact imprime et inspecte les étiquettes à l'aide de la technologie Smart ou de la caméra haute résolution. Les étiquettes défectueuses sont détectées et peuvent être retirées avant d'être appliquées sur les produits, ce qui garantit que seules les étiquettes correctes sont utilisées.

Conception du système

Nombre de dispositifs de lecture

Conçu pour sérialiser efficacement les petits lots ou les produits surdimensionnés en faisant glisser manuellement le carton du produit le long de l'unité d'impression. Un code unique est imprimé, vérifié et sérialisé par une caméra intelligente.

Conception du système

Nombre de dispositifs de lecture

Système de sérialisation compact pour une intégration facile dans les lignes de production. Exécute toutes les fonctions de sérialisation, y compris le marquage, l'enregistrement et la vérification de toutes les données de sérialisation.

Conception du système

Nombre de dispositifs de lecture

Marquage et vérification de la qualité d'impression sur l'emballage des produits avec trois types de vérification disponibles : Présence, Qualité et Contrôle de référence. S'intègre directement sur les lignes de production ou à l'intérieur des machines d'emballage, en se connectant facilement aux imprimantes existantes.

Conception du système

Nombre de dispositifs de lecture

Sérialisez un large éventail d'articles orientés, tels que des cartons, des paquets ou des étiquettes, en utilisant jusqu'à 4 caméras intelligentes. Les composants modulaires et compacts, qui ont fait leurs preuves dans l'industrie, facilitent l'intégration dans diverses lignes de production ou machines d'emballage.

Conception du système

Nombre de dispositifs de lecture

Regroupez une large gamme de produits, article par article, dans des caisses ou des palettes, en utilisant jusqu'à 3 caméras intelligentes. Les composants modulaires et compacts, qui ont fait leurs preuves dans l'industrie, facilitent l'intégration dans diverses lignes de production ou machines d'emballage.

Conception du système

Nombre de dispositifs de lecture

S'installe dans les encaisseuses ou les palettiseurs existants ou nouveaux pour améliorer l'efficacité du processus en permettant l'agrégation de plusieurs articles en une seule étape à l'aide d'une caméra à haute résolution.

Conception du système

Nombre de dispositifs de lecture

Marquage et vérification de la qualité d'impression sur des emballages ronds à l'aide de 6 capteurs d'image permettant de capturer une vue complète à 360°. Trois types de vérification sont disponibles : Présence, Qualité et Contrôle de référence. Les imprimantes existantes peuvent être facilement intégrées.

Conception du système

Nombre de dispositifs de lecture

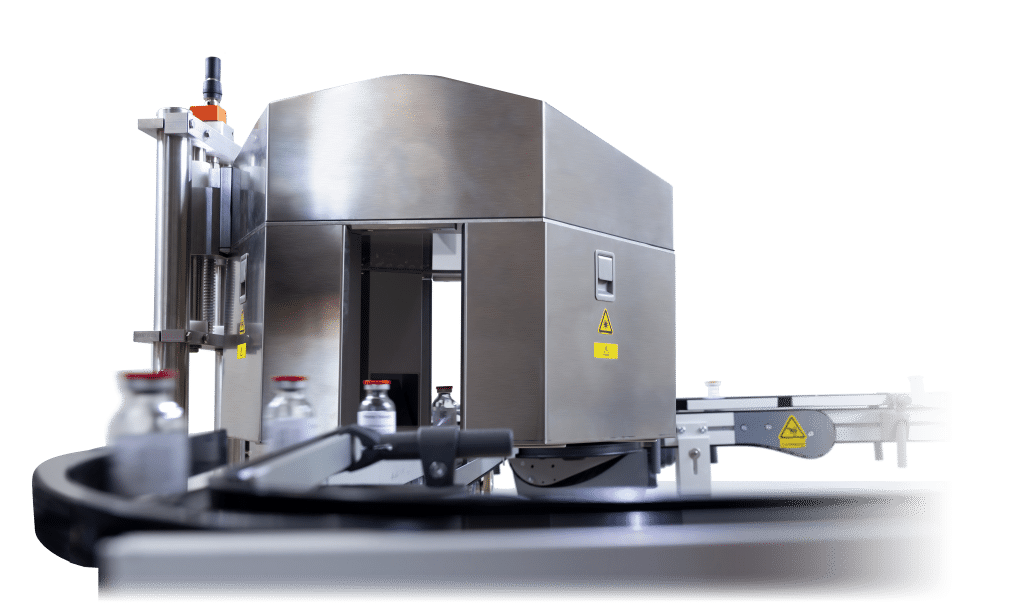

La sérialisation utilise 6 capteurs d'image pour capturer une vue à 360° de n'importe quel contenant rond, comme les bouteilles ou les flacons. La conception compacte est optimisée pour s'adapter aux convoyeurs existants afin de perturber le moins possible les lignes de production.

Conception du système

Nombre de dispositifs de lecture

La configuration de 6 capteurs d'image permet d'obtenir une vue à 360° des emballages ronds en ligne en vue de leur regroupement dans des emballages secondaires (boîtes, caisses, palettes). Élimine la nécessité d'un équipement supplémentaire pour inspecter les codes généralement imprimés sur les couvercles ou les bouchons.

Conception du système

Nombre de dispositifs de lecture

Intègre trois applications dans un système de sérialisation compact. Impression, vérification visuelle du code et scellage sécurisé et inviolable pour une conformité à la traçabilité globale.

Conception du système

Nombre de dispositifs de lecture